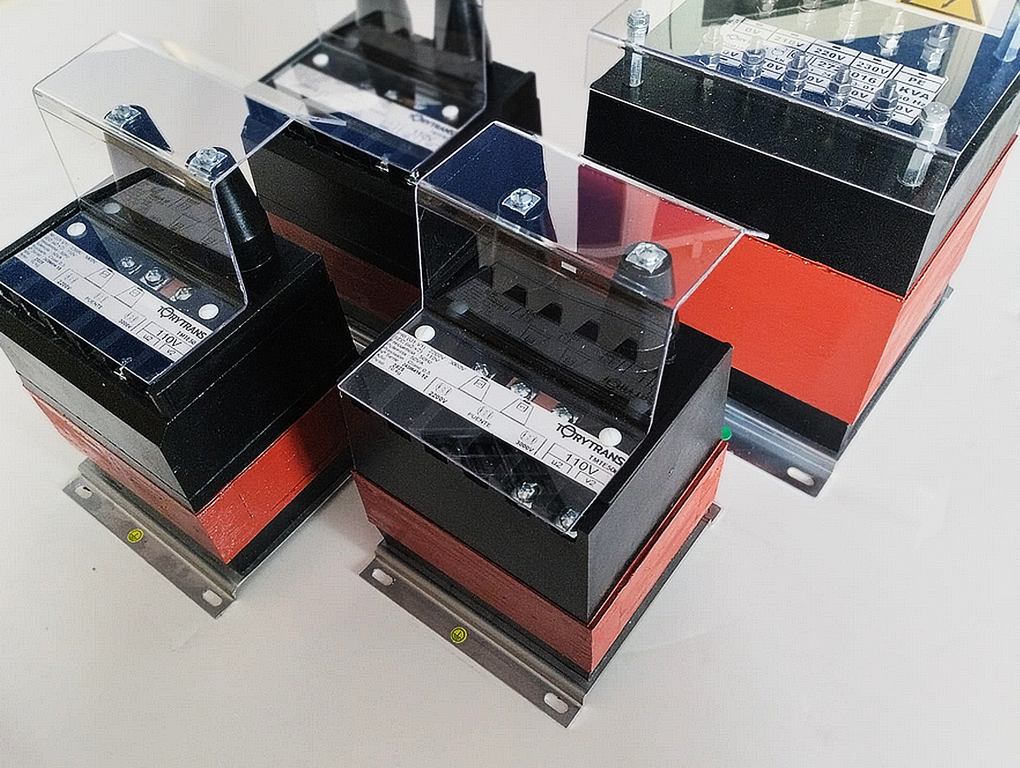

More than 25 years of experience have allowed us to develop our own technologies for improvement and innovation in Torytrans products. Our facilities have unique manufacturing processes that are perfectly adapted to the needs of our customers and the demands of today's market. The aim is always to improve the quality and finishes of our products through efficient production and a design of the Torytrans brand.

Resin Encapsulation

Torytrans has its own systems for the encapsulation of transformers and reactors with a technique that has been developed along many years with our resources and materials, in order to ensure high finished and safety products. These encapsulation techniques could improve its electrical and mechanical properties.

Between the multiple advantages of encapsulation the following may be highlighted:

- Eliminates winding electrodynamic forces and extends the life of the isolations

- Completely sealed internal electrical connections

- Protection against high moisture and corrosive environments

- Noise and vibration reduction of the transformer

- Increased protection against electric shock

- Indicated for environments with vibration movements

- Extend the useful life

Vacuum Pressure Impregnation (VPI)

Torytrans nowdays offers to customers any finishing option that is required for our own manufactured products. We have different lines of impregnation fully automated that control all varnishing as pressure processes, time and temperature of drying, avoiding human errors and being respectful to the environment.

Among the multiple advantages of this process (VPI) the following can be noted:

- Corrosion protection

- Improve the dielectric withstand

- Increase the compaction of windings and core

- Reduce vibration and noise

- Extend the useful life

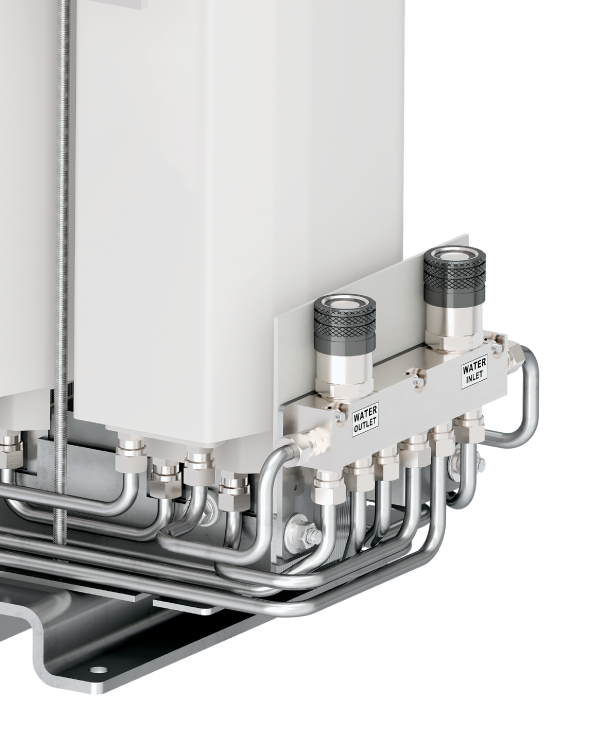

Liquid cooling

As other electrical machines, core and windings losses in the transformer or inductor during operation are converted to thermal energy and heat the remaining parts or surfaces.

Air forced cooling systems sometimes can not dissipate all the heat produced and due to its final size it can not be installed for occupying a large space. For high powers it is necessary to dissipate more heat and propose a liquid cooling system. By introducing a cooling fluid through the windings of the transformer or reactor and a cooling circuit follow a more direct and efficient cooling will be reached.

Torytrans in his commitment to innovation and technological improvements could offer to our customers the latest advances in liquid cooling systems. Water, oil and other liquid dielectrics are needed to protect equipment from high temperatures and excessive heating.

Monitoring & Control

Transformers, reactors, filters and other equipments of Torytrans sometimes are designed to be installed on electrical networks that need to be improved and controlled, either on the same location or remotely. Some applications provide priority to the control, monitoring and supervision of the operating conditions. In this way, it will provide accurate information about their state, that allow us to prolong the service life of all components and reduce costs, due to lower maintenance requirements and increased availability.

Among different control options, we can highlight the following:

- Network analyzers and controllers

- RS232, RS485

- Ethernet

- GSM, GPRS, TCP/IP

- Alarms and messages

- Master-Slave Configuration

- PCB & Control cards